Your Trusted LVT & SPC & Loose Lay Flooring Factory Partner from China

Adasea Flooring is a specialized PVC, LVT, and SPC , Loose lay flooring manufacturer based in China, dedicated exclusively to B2B wholesale partnerships. Unlike trading companies that rely on third-party suppliers, we operate five modern production lines, giving you direct access to consistent quality, competitive pricing, and reliable delivery schedules.

For over a decade, we've been the trusted manufacturing partner for flooring distributors, construction contractors, and brand owners across North America, Singapore, Japan, and Vietnam. Our team understands your challenges—fluctuating quality from unreliable suppliers, delayed shipments, and complicated communication—and we've built our operation to eliminate these pain points.

With in-house production control, verified certifications, and an English-speaking sales team available around the clock, we deliver not just flooring products, but peace of mind for your business growth.

Ready to work with a factory that understands your business needs?

Start Your PartnershipWho We Work Best With

We specialize in serving B2B partners who value consistent quality, transparent communication, and reliable delivery schedules

Flooring Distributors & Wholesalers

You need stable pricing, verified certifications, and consistent stock availability to support your retail network and maintain competitive margins.

We provide transparent factory pricing, bulk discounts for container orders, and production planning visibility so you can commit to your customers with confidence.

Construction Boss & Project Contractors

Your projects require punctual delivery, batch consistency, and local compliance documentation—delays or quality issues impact your reputation and penalties.

Our production schedule tracking, pre-shipment QC reports, and verified SGS/CE certificates ensure your projects stay on timeline with zero compliance surprises.

Brand Owners Needing OEM/ODM Ranges

You want to launch your own flooring line without investing in manufacturing infrastructure, but worry about MOQs, design flexibility, and quality control.

We offer customizable embossing patterns, private label packaging with low MOQs (3,000 SQM), and sample approval processes that give you full creative control without production risks.

Online Sellers Testing New Markets

You're exploring eCommerce opportunities on Amazon or your own website but need smaller initial orders, fast sampling, and responsive communication for market validation.

We support test orders from 1,000 SQM with flexible payment terms, expedited sample shipping (3-5 days), and guidance on packaging that reduces damage rates for direct-to-consumer shipping.

See yourself in one of these categories? Let's talk about your specific needs.

Share Your RequirementsWhy Choose Adasea as Your Flooring Partner

We solve the real problems that keep flooring buyers awake at night—inconsistent quality, communication delays, and delivery uncertainty

Clear Communication & Fast Response

No more chasing vague responses. Our English-speaking team replies within 1-3 hours with detailed quotations that include specifications, MOQs, and realistic timelines—eliminating guesswork from your sourcing decisions.

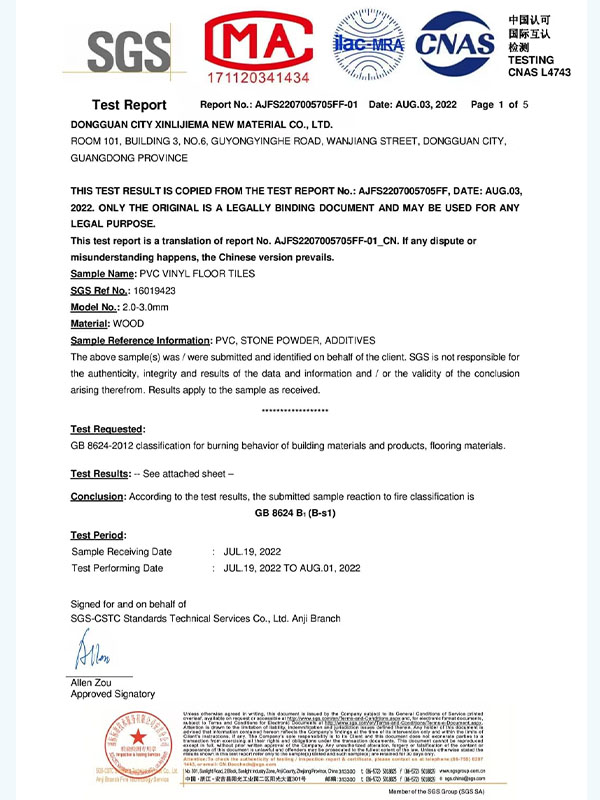

Verified Certifications You Can Trust

Every batch comes with traceable SGS and CE reports linked to your specific order. We support local third-party testing if required and provide batch-specific documentation that passes customs and project audits without delays.

Predictable Delivery & Production Visibility

See exactly where your order stands with production schedule updates, loading photos, and shipment tracking. This transparency means you can commit delivery dates to your own clients without anxiety about supplier delays.

Technical Support for Non-Technical Buyers

Don't understand wear layer thickness or click-lock systems? We provide simple specification comparison charts and installation guides that help you confidently explain product benefits to your end customers without needing engineering knowledge.

Experience the difference of working with a partner who understands your challenges.

Request a QuoteInside Our Factory

5 Modern Production Lines Ensuring Consistent Supply for Your Growing Business

Unlike trading companies that depend on external suppliers, our owned manufacturing facility gives you direct control over quality, timing, and customization

Raw Material Control

We maintain consistent PVC formulations without cost-cutting substitutions that compromise durability. Stable raw material sourcing means your reorders match previous batches in color, texture, and performance—critical for project consistency.

Production Excellence

Our automated extrusion, calendering, and UV coating lines operate with precision monitoring at every stage. From mixing through embossing, grooving, beveling, and packaging, quality checkpoints prevent defects from reaching your warehouse.

Warehouse & Container Loading

Temperature-controlled storage prevents warping before shipment, and our experienced loading team uses protective corner guards and strategic placement to minimize transit damage. You receive your order in sellable condition, not replacement-requiring condition.

Want to see our production process in action? Schedule a video factory tour.

Book a Virtual TourQuality Control & Certifications You Can Verify

Every batch undergoes rigorous testing with documented results you can trace—eliminating quality surprises and customs delays

Our Quality Control Process

PVC resin purity, plasticizer content, and stabilizer ratios tested before production starts. This prevents formula variations that cause color shifts or brittleness in your finished orders.

Thickness gauges, visual inspection stations, and wear layer verification at multiple production stages catch defects immediately, reducing the chance of full-batch rejections at your end.

Dimensional accuracy, color consistency across batches, and click-lock functionality tested on random samples. Ensures your installers don't face surprises when opening cartons on job sites.

SGS reports for phthalates, formaldehyde, and heavy metals included with every shipment. Traceable batch numbers mean you can confidently answer customer questions and pass local inspections.

Verified Certifications & Reports

Independent lab verification for phthalates, formaldehyde & heavy metals

European compliance for construction products safety standards

Indoor air quality certification for VOC emissions control

R9-R11 rating reports for commercial safety requirements

Need specific test reports or third-party verification? We support your requirements.

Request Test ReportsReal Results with Our Partners

See how we've helped distributors, contractors, and brand owners overcome their flooring supply challenges

Previous supplier provided inconsistent color batches and slow email responses, causing customer complaints and lost retail accounts during peak season.

Implemented batch-tracking system with pre-production samples, dedicated account manager responding within 2 hours, and advance production scheduling for seasonal demand.

Result: 6 containers monthly for 18 months with 98% on-time delivery, complaint rate dropped from 12% to under 2%, enabling 40% revenue growth.

Hotel renovation project required 15,000 SQM with strict fire-rating certificates and 4-week delivery window. Previous factory couldn't guarantee timeline or documentation.

Expedited production with daily progress photos, arranged SGS fire-rating tests matching Singapore regulations, and coordinated with freight forwarder for door-to-site delivery.

Result: Delivered 3 days ahead of installation deadline with all compliance documents, contractor awarded 3 additional projects based on this success story.

Wanted to launch premium LVT line under own brand but lacked manufacturing expertise. Concerned about quality consistency and minimum order requirements.

Developed 5 custom embossing patterns with 3D renderings for approval, designed branded packaging at 3,000 SQM MOQ, and provided installation guides with QR codes linking to their website.

Result: Launched successfully in 8 US states, reordered every 2 months with expanding product range, brand now commands 25% premium over generic competitors.

Ready to write your own success story? Let's discuss your specific challenges.

Start Your ProjectHow We Work with You

A transparent, step-by-step process designed for buyers who value clarity and predictability over uncertainty

Share Your Requirements

Tell us about your market, target customers, and flooring specifications. We'll ask smart questions to understand your real needs.

Get Proposal & Samples

Receive detailed quotation with product specs, MOQs, and realistic delivery timelines. Order samples to test quality firsthand.

Confirm Order Plan

Finalize design, packaging requirements, and order quantity. We create production schedule and send proforma invoice for deposit.

Production & Quality Control

Track production progress with updates and photos. QC inspection before packing, loading photos shared before shipment departure.

Long-Term Partnership

Enjoy priority production slots for reorders. We proactively suggest new products based on your market feedback and trends.

Tell Us About Your Market and We Will Suggest a Practical LVT & SPC & Loose Lay Flooring Range for You

Whether you're a distributor evaluating new suppliers, a contractor with an urgent project, or a brand owner exploring OEM options—let's start the conversation.

Send Your Inquiryinfo@adaseaflooring.com

Reply within 1-3 hours

+86 13527669798

24/7 English support

Click bottom-right corner

Instant connection to our team